Personalized design, high separating accuracy. According to the characteristics of different coal types, wet coal, lump coal and fine coal can be sorted respectively, and the separating accuracy is guaranteed.

Fully enclosed operation, good environmental protection effect, equipped with self-developed all bags dust collection equipment, no dust overflow, good environmental protection effect.

Modular configuration, without civil engineering, it can be put into operation quickly. The whole machine adopts modular configuration without huge civil engineering. A 3 million tons coal preparation plant can be put into operation in 30 days.

Automatic centralized control system and intelligent control truly realize manned patrol and unattended.

Send EmailMore

- Home

- Products

- ZM High-efficiency Mineral Separator

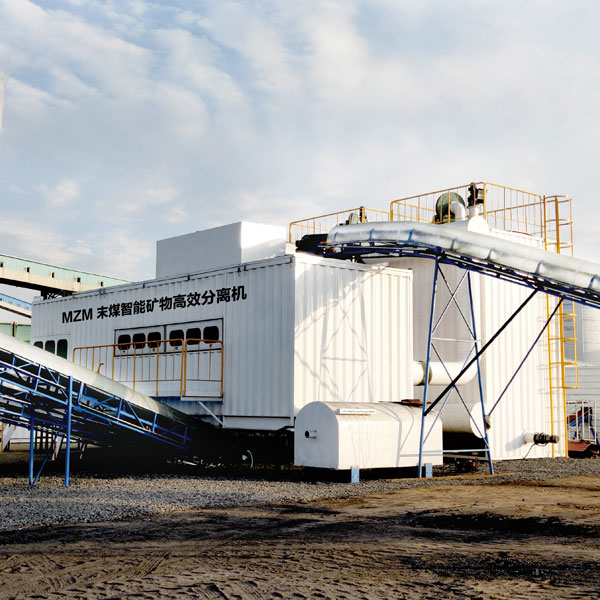

- MZM Intelligent Dry Separator For Fine Coal

- CZM Intelligent Super Dry Separator

- JZM Multi-stage Dry Separator

- FGX Compound Dry Coal Separation Technology

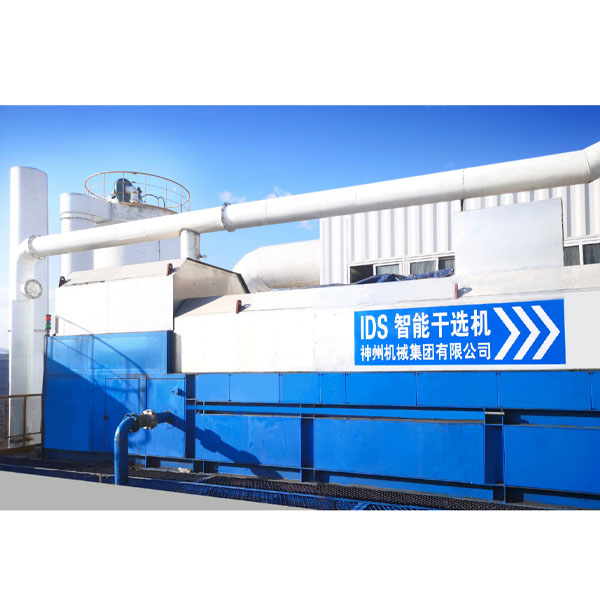

- Intelligent Dry Separator

- IDS-M Type Underground Intelligent Dry Separator

- Full Size Fraction Dry Coal Preparation System

- GZQ Dry Dense Medium Vessel Separation Technology

- MFD Vibration And Mixed Flow DryingTechnology

- Intelligent Management System

- Screening And Crushing Series Of Products

- ZM High-efficiency Mineral Separator

- News

- Case

- Factory Show

- Contact Us

- About Us