Tangshan Shenzhou Manufacturing Group Co., Ltd. is located in Tangshan City, Hebei Province, China, at the core of the Bohai Rim economic circle. The company was founded in 2001 with a registered capital of 100 million yuan, covering an area of more than 200 acres. The company has all kinds of advanced large-scale processing and manufacturing equipment. After years of development, Shenzhou Manufacturing Group has formed a high-tech enterprise integrating new coal preparation technology, new equipment development, coal preparation engineering design and consulting, coal preparation equipment manufacturing, and coal preparation and processing services, which has established wholly-owned subsidiaries in the US and Australia and has built national coal dry processing equipment engineering technology research centers and dry coal processing engineering centers for the coal industry.

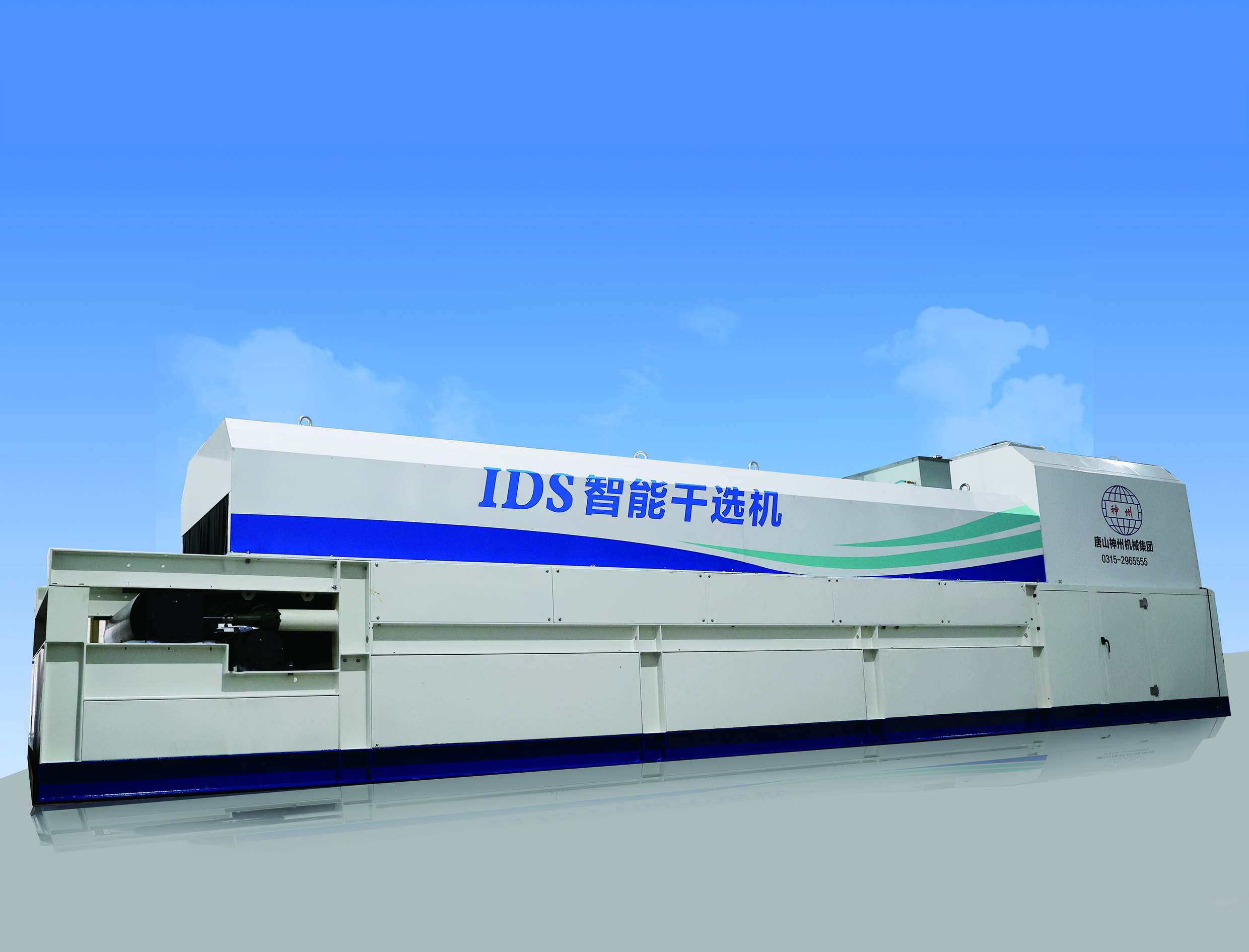

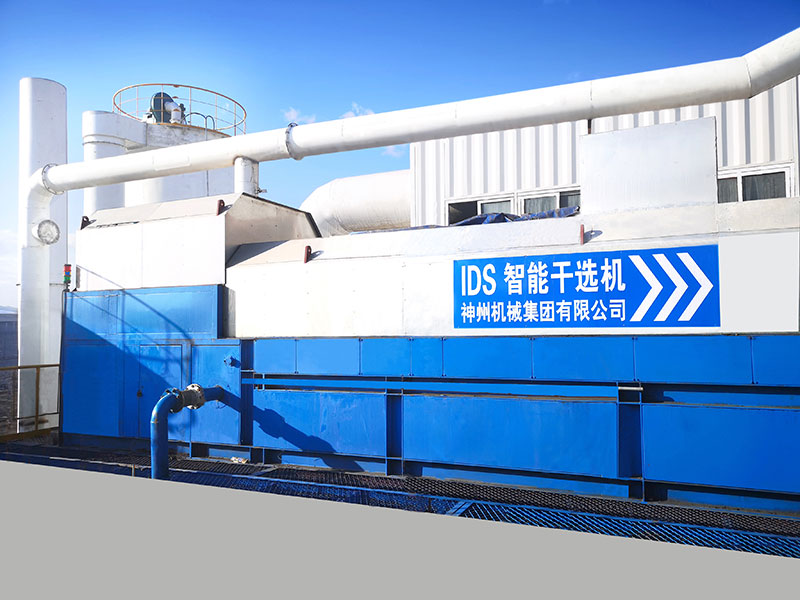

The company has more than 100 authorized domestic and foreign patents, including more than 40 invention patents, 15 international patents, and 26 software copyrights. The company’s main products are FGX composite dry separation equipment, ZM mineral high-efficiency separator dry coal preparation equipment, IDS intelligent dry separation equipment, GZQ dry reagent sorting equipment, MFD mixed flow drying equipment, environmentally friendly dust removal equipment, screening and crushing equipment, and intelligent electrical automation systems.

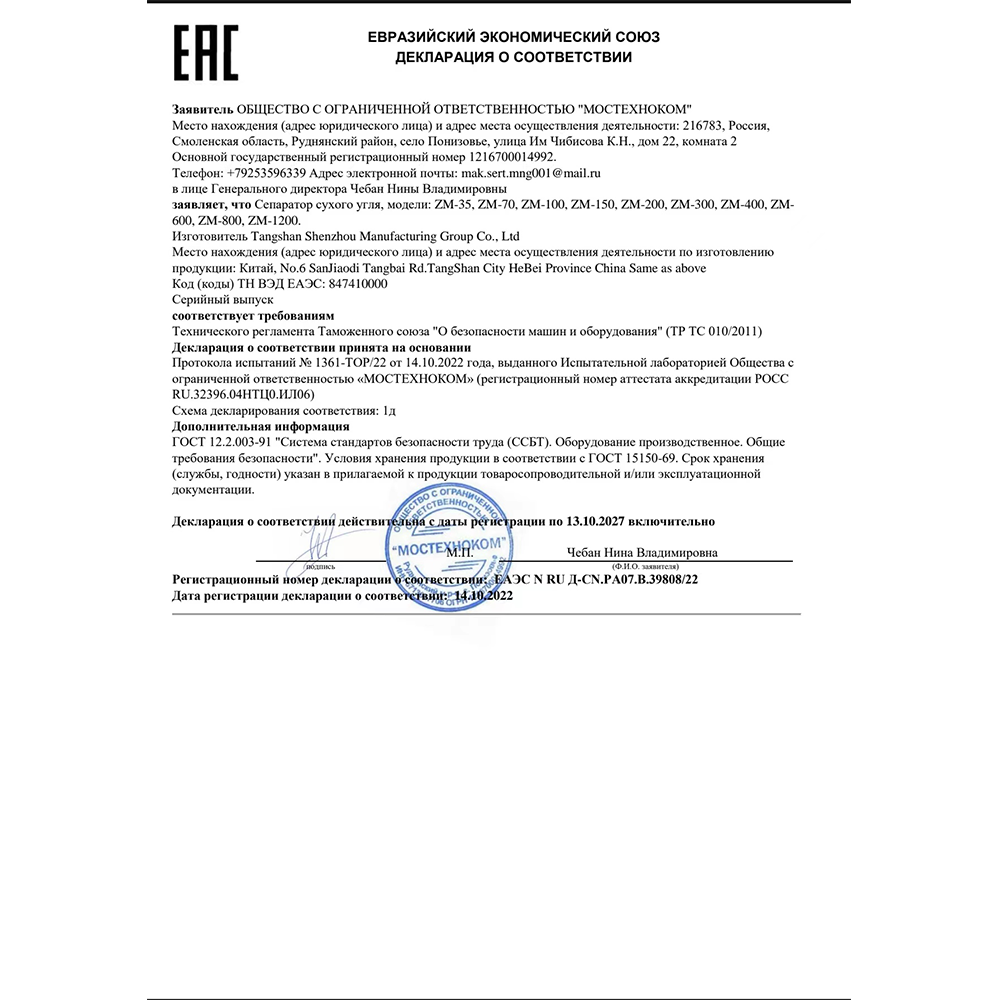

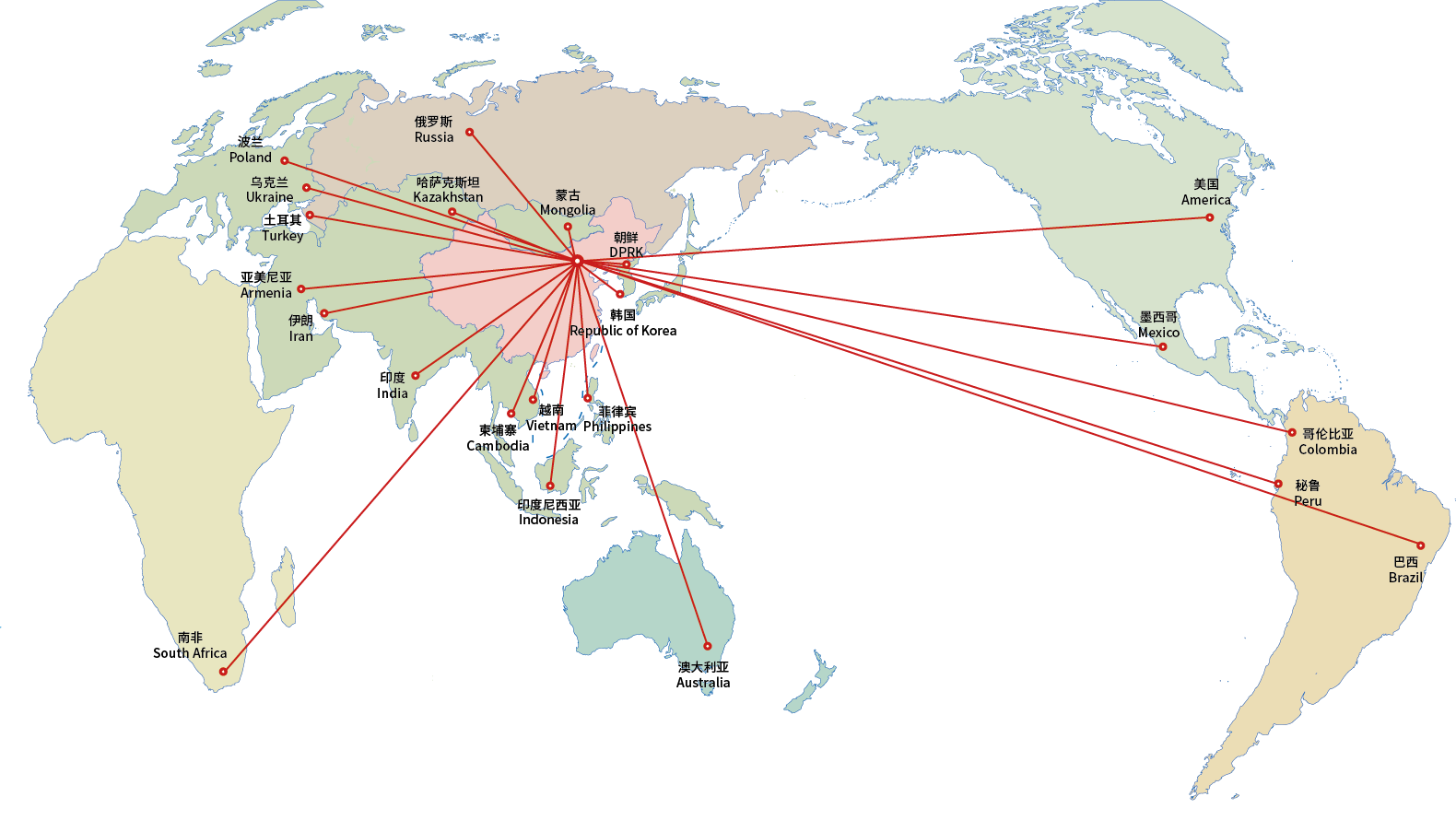

After more than 20 years of development, the products of Shenzhou Manufacturing Group have been exported to 23 countries including the United States, Russia, Kazakhstan, Ukraine, Poland, Turkey, South Africa, India, Brazil, and Indonesia, and its products have spread across 26 provinces, cities, and autonomous regions in China.

Shenzhou Manufacturing Group is willing to work with countries around the world to grasp the new trends in the dry coal processing era, deepen international exchanges and cooperation in the field of intelligent dry coal processing, promote the innovation and development of the intelligent dry coal processing industry, and work together to create a more environmentally friendly and wonderful future.

Development of compound dry separator

The development of dry coal preparation technology in Shenzhou is a mirror of the development of dry coal preparation technology in China, and also a significant part of the development history of coal preparation. The development of dry coal preparation technology in Shenzhou has set off a coal preparation technology revolution of "replacing water with wind", and has made great contributions to the coal preparation cause in China and even the world. In 1997, the FGX-1 compound dry separator developed by the technical team headed by Li Gongmin, chairman of Tangshan Shenzhou Manufacturing Group Co., Ltd. (the predecessor of Tangshan Shenzhou Manufacturing Group Co., Ltd.), was put into use in Wuchang Coal Mine, Gujiao, Shanxi Province. It was the first equipment used in the promotion of Shenzhou dry separation technology, filling the blank of dry separation in the field of coal preparation. Tangshan Shenzhou Manufacturing Co., Ltd. was officially established in 2001.

The development of dry separation technology has entered a fast track, with the production capacity of up to 480t/h. By 2010, the number of sets sold in China has reached more than 1500, and they have been exported to 11 countries. The continuous innovation and upgrading of products, the gradual large-scale and automation of the system are the intermediate stage of the development of dry separation technology, providing a solid foundation for the subsequent development. In 2013, the dry separation technology of Shenzhou has made a qualitative leap. More high-end dry separation technology ZM mineral high-efficiency separator has been developed successively, and the BOO and BOT service modes have been introduced at the stage of new technology promotion. Once the product is launched, it is highly recognized by the coal industry. Shenzhou always adheres to the concept of scientific and technological innovation, pursues the spirit of outstanding craftsmanship, and continues to innovate at the forefront of dry separation technology. Intelligent mineral high efficiency separator for lump coal and intelligent mineral high efficiency separator for fine coal have been developed according to the different feeding granularity.

In 2020, Shenzhou Group has developed JZM intelligent ladder separator according to the requirements of deep reject discharge of coking coal; In response to the national energy-saving requirements, CZM intelligent super dry separator has been developed. The research of Shenzhou Group in the field of composite dry coal preparation technology has never stopped, and customer demand is our driving force for continuous progress. In order to solve the technical problem of all size dry separation, IDS intelligent dry separator has been developed specifically for the separation of large blocks of coal above 50 mm. This technology uses X-ray identification, which completely replaces manual selection and avoids the ineffective crushing of large blocks of reject. In order to solve the problem that wet coal is difficult to be selected, DDU intelligent double dry upgrading equipment has been developed, that is to improve the separation conditions on the basis of water removal and quality improvement, so as to achieve the double quality improvement effect of precipitation and reject removal. In order to achieve ultra-low ash dry separation, Shenzhou Group and China University of Mining and Technology jointly developed the GZQ dry dense medium separator, which realizes the separation of coking clean coal, chemical clean coal and other non coal minerals with high density, and is a leading technology of dry separation.