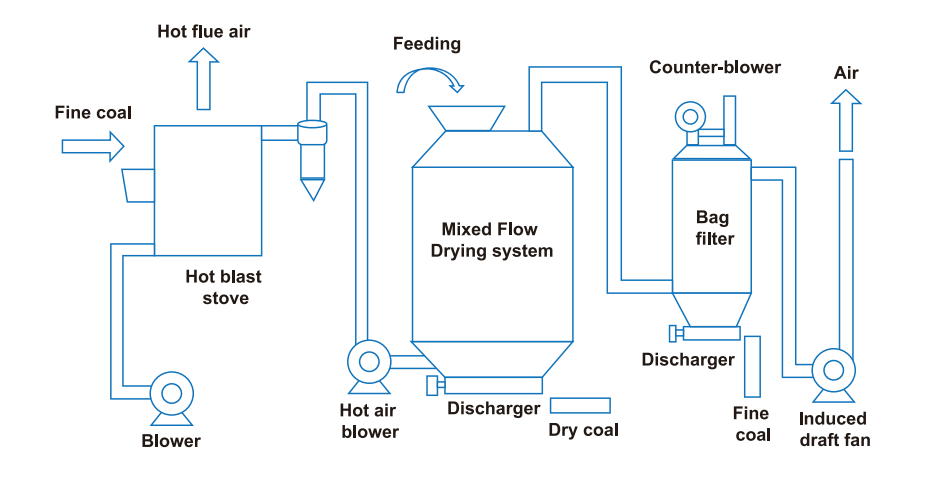

Vibration And Mixed Flow DryingTechnology

In view of the characteristics of low rank bituminous coal, such as high volatile matter and low ignition point, Shenzhou Group first proposed the technical route of low temperature and large air volume drying, and independently developed the MFD mixed flow drying system. As we all know, there are many factors that affect the calorific value of coal, among which ash and moisture are the main factors. In addition to reject removal, the removal of one moisture can also increase about 70kal/kg. The successful development of the system broadens the application scope of dry separation in low rank coal with high moisture content, and can independently dry coal with high moisture content, with large water removal range and wide adjustment range. According to its unique structure and drying method, low production cost and strong production capacity, the drying system is widely used in raw coal, washed coal, slime, shale, chemical coal and other fields.